Glue Extrusion

Description

Description

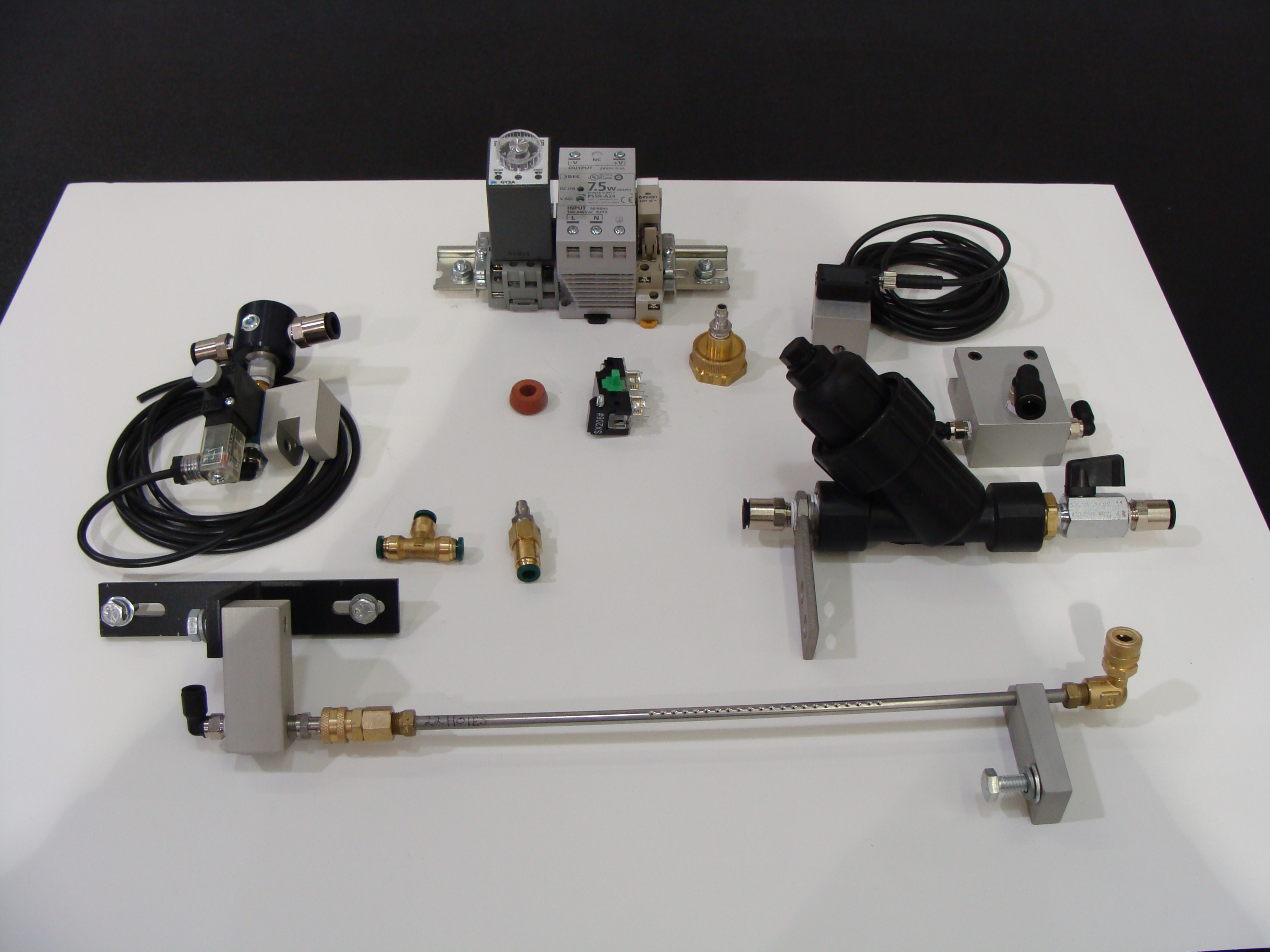

Glue Extrusion Conversion Kits for Existing XS-1250 Can Labeling Machines

Have you considered converting your Bear XS-1250 standard labeling machine to a Glue Extrusion System? We now offer a retro fit Glue Extrusion System designed specifically for your Bear Label Machine.

Here are just a few of the many advantages of retrofitting your existing Bear XS-1250 to a Glue Extrusion System.

- Easy to install (6-8 hours)

- Saves money

- Less parts to maintain

- Easy to clean

- One Year Warranty On Workmanship and Materials*

- Free Lifetime Technical Support*